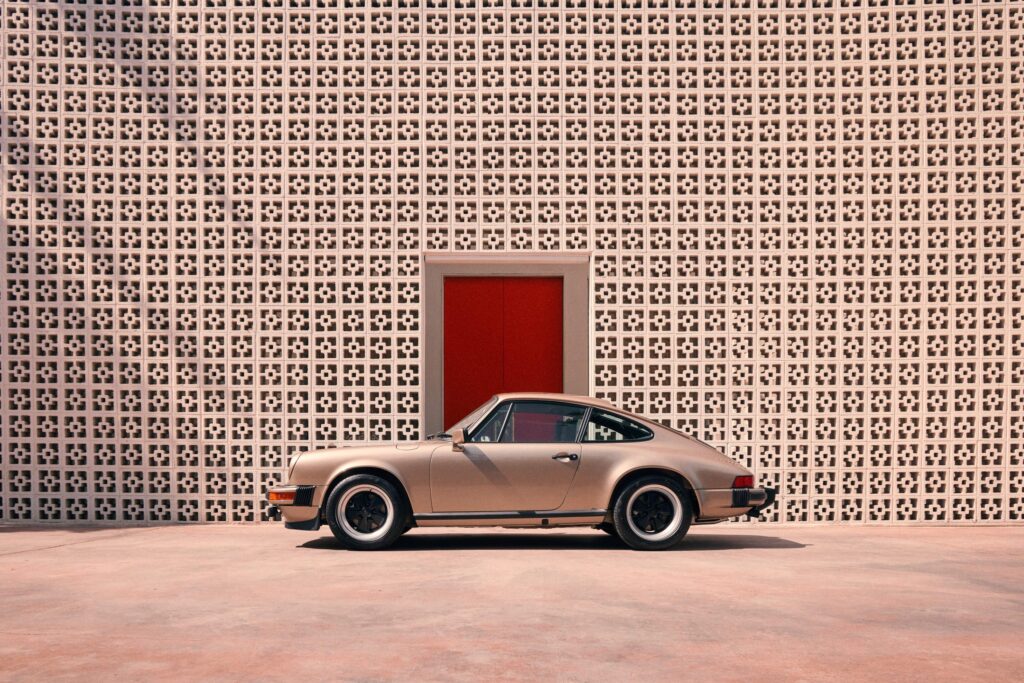

As a Porsche Classic Partner, Porsche Palm Springs is participating in the 2022 Porsche Classic Restoration Challenge.

We are competing against other regional Classic Partner dealerships in the restoration of a classic Porsche 911 SC from 1982 for the Porsche Classic Restoration Challenge.

The “Champagne Metallic” vintage Porsche restoration is being carried out by Service/Classic Partner Manager Ken Arguelles and our Classic Technician, John Ghaemmaghami. A final reveal is expected later this summer.

Among the big issues for this Porsche, restoration are a transmission that was full of water and the fact that the car’s oil had converted to sludge and the axle had fallen apart.

All of those issues are being corrected as the car is lovingly restored to perfect working order.

Among the most visible, showstopping changes to the vehicle is the all-new leather upholstery throughout the renovated interior.

For help with that, Porsche Palm Springs turned to world-class upholstery manufacturer Heritage Upholstery. The Palm Springs-based classic European auto upholstery company has been a worldwide leader in high-quality upholstery products for Porsche, Jaguar, and Mercedes classic cars for 30 years.

You May Also Like: It’s Decision Time: How Will It Measure Up?

We spoke with Heritage Upholstery founder and owner Tony Hazell to learn more about the ultra-exclusive services he offers and the unusual way he connected with Porsche Palm Springs for the Porsche Classic Restoration Challenge.

Nice to meet you Tony! Tell us about the Porsche Classic Restoration Challenge project and what sets it apart from others you have done?

We have never done work with a dealership before. This is our 30th year of business. We work all over the world – trade and retail – but never with a dealership until now.

We provide ultra-accurate full interior kits and that’s what Porsche Palm Springs needed for this particular project – to match the original spec to the highest concours standards.

Tell us about the work you do with your worldwide clientele?

We manufacture our interiors using a Computer Aided Design (CAD) cutting machine to cut the car’s rear panel where, for example, there are punched speaker holes. There’s no way to do that accurately by hand. All of the materials we use are imported from Germany – not from Porsche – and reproduced to be closer to the original specification.

With the Porsche Palm Springs car, there were quite a few parts that they needed for the interior that Porsche was not able to supply because they are hard to find. But we were able to source them from Germany. The model is a 1982 911 Carrera Coupe. We helped guide them with the interior color choices accurate to the era – and now it’s a cocoa brown.

So how does the process work?

So basically Porsche Palm Spring’s team assembles the car down to the smallest pieces as part of a high-quality rebuild to factory standards. Even the transmission was completely stripped down. And because of our extensive experience with Porsche models from the early 1950s through to the mid-1990s, we have all the patents for upholstery/dimensions digitized and so we don’t need the car and we can offer this service essentially by mail order around the world.

People actually send us the interior frames of their cars by air freight, and many times we build the interior ahead of the pieces arriving. In this particular case we could move forward, cut leather, and start manufacturing things knowing what the car is and how it will fit – and then Porsche Palm Springs brought us components from the car that are being rebuilt, including the frames. They needed replacement seat foams for front and rear and they did not have those – but we were able to source them from Germany.

With that said, we don’t normally do this, but my top guy was made available to do a house call to the car at the dealership so they wouldn’t have to move the car around. We rarely have the cars themselves in shop. It’s a big shop: 7,000 square feet and we have a crew of 10 people right now as well as a sales office in Vancouver, BC.

Tell us how you happened to end up in Coachella Valley doing this fascinating work.

I’m from Wales originally but I’m a Canadian citizen. My wife and I moved down to the desert about six years ago. We were in Vancouver BC shipping out of Washington State into the United States. It was an easy move down here. It hasn’t really changed our business being here. In fact, we do more international business than we’ve ever done. The cars we work on end up on social media when they are finished and that creates a buzz throughout the world. We work with clients in Australia, New Zealand, South Africa, Dubai, Germany, and many other places. The customers cut and ship the upholstery to retail people who are going to have it done locally and also restoration shops because it’s so specialized.

What’s it like to work internationally?

Worldwide, we only work on Porsche, Jaguar, and Mercedes.

A lot of times to do our work we need the seating frames that survive well on the cars and those come to us via air freight. There is also specialized panels and substrates – dashboard and door components- that get re-covered. We work on seat upholstery and the other panels, often around the dashboard and doors, that are leather. We have 30 to 40 full car interior packages in production at any time but do very little local business. The Porsche Classic Restoration Challenge project with Porsche Palm Springs is a standard project for us. We work to ultra-high standards and we are the best in the world and we are priced accordingly. We only do it one way whether it’s for Porsche or anyone else.

Each member of the crew at Heritage have laptops on their benches and they access our how-to videos for every piece of every component of every car. That’s thousands of different parts and processes. There’s a specific video for sewers to sew the seat covers. There’s a video for the trimmers to take those seat covers and put them onto frames.

How did this project come about?

I stopped into Porsche Palm Springs one day and was looking at an old Porsche. I was telling someone that I make the upholstery for these cars. John, the head mechanic, happened to walk past and he introduced himself to me. He said he thought he had heard of us but wasn’t sure. I checked the security camera from work (on my phone) and showed him the facility and he went “OMG!”

Suddenly, we were having a conversation and someone was saying ‘We need a door panel like this and we don’t have any of them.’ And I said, ‘Yeah I think we have about 50 of these on the shelf.’ When his colleague later came in to see the facility he told our people they had a classics project coming up, the Porsche Classic Restoration Challenge.

How did you get into this line of business?

I am an electrician by trade. Thirty years ago I had a very good job in a telephone company. I was a well-paid industrial electrician. As a hobby, I went back overseas and met people in the classic car upholstery business and started working on Jaguars and then got into Porsches and Mercedes – and strictly no other cars. I was restoring a Jaguar car of my own. I personally have never done this work hands-on. But I know every aspect and understand every aspect of our production. I know everything down to the correct tension of the thread for the sewing machine. My wife and I own the business together. And I have been doing it since before the CAD technology came along. Our crew used to hand cut like they did in the factories and then they tool cut, using sharp blades that are like large cookie cutter blades that are hit with a hydraulic press machine that cuts through boards. Now everything is cut with our machines.

Now, for instance, the operator rolls out the original spec carpet onto the bed of the Gerber machine presses a button for any Porsche carpet and it’s set to cut to precisely the original pattern in about one minute and 30 seconds – and it never fails to make me smile.

I urge anyone who is interested in what we do to look at the photos and videos section on our web page at www.heritagetrim.com

Check out our latest: